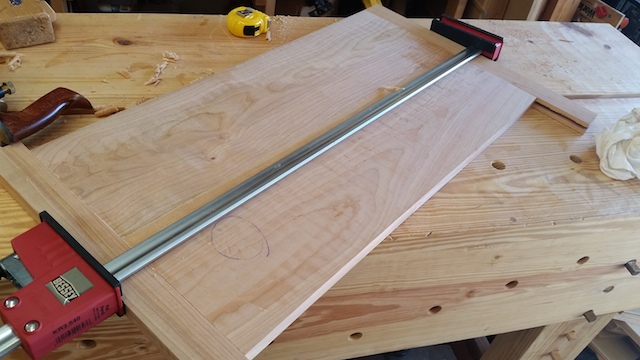

So, after I got the parts all milled and cut out for the chest frame, I decided I would turn my attention to the lid of the chest, just to get it a little closer to finished, There was a little unevenness, and I thought initially that I would give the belt sander a go to get things ironed out.

Of course, as luck would have it, I didn’t have a coarse enough belt to do any type of leveling, just a 120 grit which takes a little too much time to abrasively plane the wood down. Something like an 80 grit – FRESH out of the package – would have been a smarter pick.

Oh, well, there was a quieter, more traditional way to do the deed. Hand planes. If you speak with a hand plane enthusiast, they will tell you in glowing, nearly poetic terms how deftly and gently they can do the work of smoothing pieces out, leaving them ready for a final finish with barely a drop of sweat on your brow.

Yeah, right. I did feel for the worst spots (one area was about 1/16″ high…), so I figured I would start out with my #5 jack plane. And, it did OK, shaving off the high areas and leaving a not too terrible surface. Knowing this was just the first step, I wasn’t going to sweat this at all.

So, I figured I would move toward my next step – my jointing plane. I figured, “Hey, I want the lid of this chest to be nice and dead flat. Why not run the plane over the lid and let the long sole get a good, flat surface on things.

Well, gosh, that worked well – for a while. In the middle of the panel it cut like butter, I was making such awesome progress, just feeling like the unicorns were dancing on rainbows right there in my very shop.

That’s when things went sideways. Or, maybe I should have reversed the grain direction. When I got to the breadboard edges, I pushed along the grain with the jointer plane. I’m pretty sure either I had too much iron exposed, the mouth too open or I was a complete hammerhead, and it just tore out like an S.O.B.

Bummer.

Now, I have to decide what will be the best way to fix this problem. I’m thinking of perhaps just flipping the board direction, planing until the tear out is gone, then reduce the amount of iron exposed to try again.

Of course, a friend with a wide belt sander would be someone I use right about now…