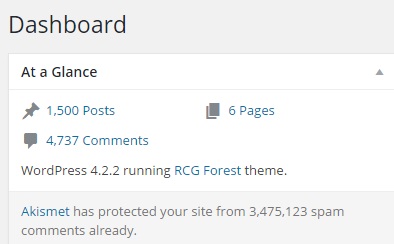

In addition to celebrating my 1,500th post this week, I was also at the Governor’s Hurricane Conference teaching emergency responders how to work with the media. It was a great class, and I have got to tell you that I had a ton of fun.

OK, maybe a little too much fun, but who cares, right?

A big part of our classwork is helping our aspiring public information officers understand where they fit in during a disaster. And, according to FEMA, there is a very specific place where they do belong – front and center. That is a major rule laid out by the Incident Command System, which operates under they National Incident Management System.

Public information shares that top billing along with the Liaison officer, whose job it is to coordinate between agencies outside of the responding agencies, and the Safety officer, whose job it is to ensure that everyone gets home without injury if at all possible. Together, these three officers and the Incident Commander make up the Command staff.

Now that you are thoroughly bored, let me ask you why those three positions are so close to the Incident Commander? The reason? Well, it comes back to an old expression – out of sight, out of mind.

Without a PIO, the needs of the citizens will be forgotten. Without a Liaison officer, the incident can become siloed, and no one thinks to reach out to the other affected organizations. And, if safety is overlooked, people get hurt or die.

With today being Woodworker Safety Day, how much time do you spend thinking about safety in your shop, or is it an issue of out of sight, out of mind? Sure, the tools we buy all come with operators manuals, but how many of us just skip by the safety warnings inside them? How many of us remove the safety devices from our tools because they get in the way? How many times do we make that one last cut and forget to grab the eye or hearing protection?

It happens. And, for the vast majority of times, nothing ever happens.

But, just as with any accident, that split second of carelessness can jump up and bite us hard. That’s why we have to think like Incident Commanders and ensure that we put safety front and center.

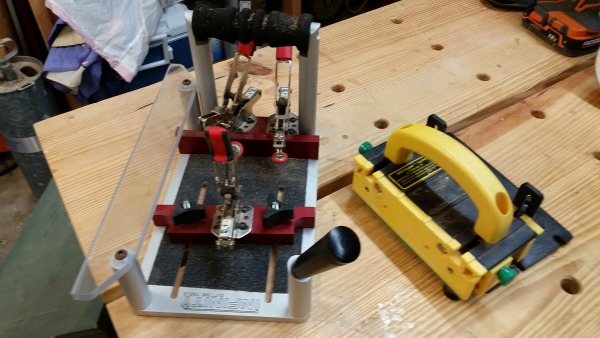

For instance, I know that my old table saw’s splitter did create an area where kickback could occur on behind the blade, but my new saw’s riving knife is a much safer option. I always keep my push sticks and other sleds handy, because I can work with more confidence at the power tools.

I keep my eye protection close at hand. After having my share of accidents where I was able to walk away from them with minimal damage, I am very happy to take the time to ensure safety is job number one, two and three.

While it may not be the sexiest part of woodworking, safety gear keeps you in the shop in command of your tools. After all, isn’t that the best part?

While it may not be the sexiest part of woodworking, safety gear keeps you in the shop in command of your tools. After all, isn’t that the best part?