OK, so first my wife invaded the shop, then my oldest son Dominic… now my youngest has joined the effort, and I couldn’t be any happier.

You see, with the summer vacation coming very quickly, my sons have seemed to switch off to take some well-deserved rest. But, of course, we have to keep them moving. Active with the house work. Doing their summer homework. And learning new things.

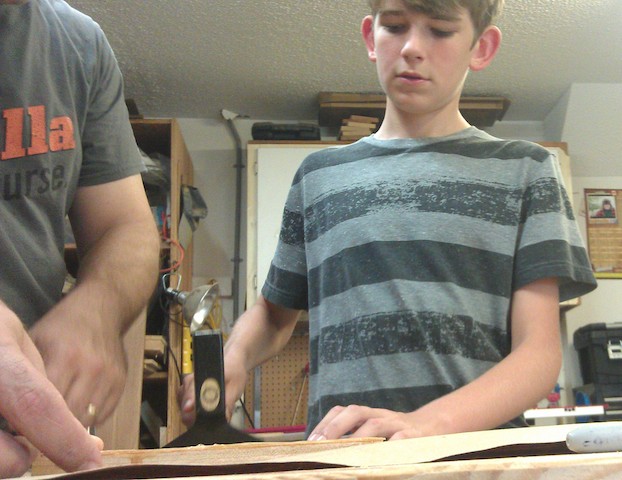

So, when Steven saw my veneer hammer and started asking questions, well, I just had to shift gears and give him his first veneer adventure. He liked it so much, he put together the following narrative. I hope you like this!

Hello everyone. Today I worked in the shop with my dad, well…veneering!

It was quite the job. We had to first find the right piece of wood for the project. (We picked out a piece of cabinet grade plywood to serve as our substrate – TI) We then had to get the thin piece of wood we call veneer. (He picked out a nice piece of figured maple…. it was sweet! – TI)

But first, we had to soften the veneer with veneer softener.

We had to then heat up the glue for the veneering since we store it in the fridge. (It was at this point that Steven announced that the hide glue we were using smelled like solid cow farts… I love that boy! – TI) We couldn’t quite get it to temperature, but it still melted.

We then applied it to the, “bad side” of the veneer, and the block of wood. We then flipped over the veneer and applied glue to the other side.

We then flattened it with the veneer hammer, and after rinse, lather, repeat, we were done.

P.S: We still had to wash our fingers.

You bet we still had to wash our fingers! That was some messy work with the hot hide glue, but the veneer laid down perfectly, sticking tight and flat to the substrate.

Once I gave the glue some time to dry, I trimmed the edges of the board on the table saw and broke out my random orbit sander with a 180 grit pad. The piece came out looking great, and super smooth.

After that, I wiped the dust off and wiped on a coat of finish. The grain just popped. Steven originally wanted to put it into a project, but after he saw it, he just wanted the board to display in his room.

And, I couldn’t possibly be any happier.

Well done !

You can tell, Steven is a natural !

That’s great! I love when something like this happens between me and my kids, to feel like you are teaching them some skill that they can use in a craft, career, or just to be able to better understand the world is a great parental accomplishment.

Tom,

It’s great news that your son had fun in the shop with you. Now you have to have a couple of fun projects waiting in the wings for when he comes back out again.

happy days

Great post Tom and Steven. Tom, I haven’t forgotten that I owe you a similar picture. I was given a prize for your 1000th post competition and was sent a veneering kit from one of your contributors. We finally stopped doing the travel nursing gig and settled in Birmingham. My shop is finally coming together and I finally found that stack of veneer samples that I bought 5 years ago. Yes, I think that I have finally found a round “tuit” amongst the all the stuff………..Hhhhhhhmmmmmm……….. now where did I put that veneer kit?