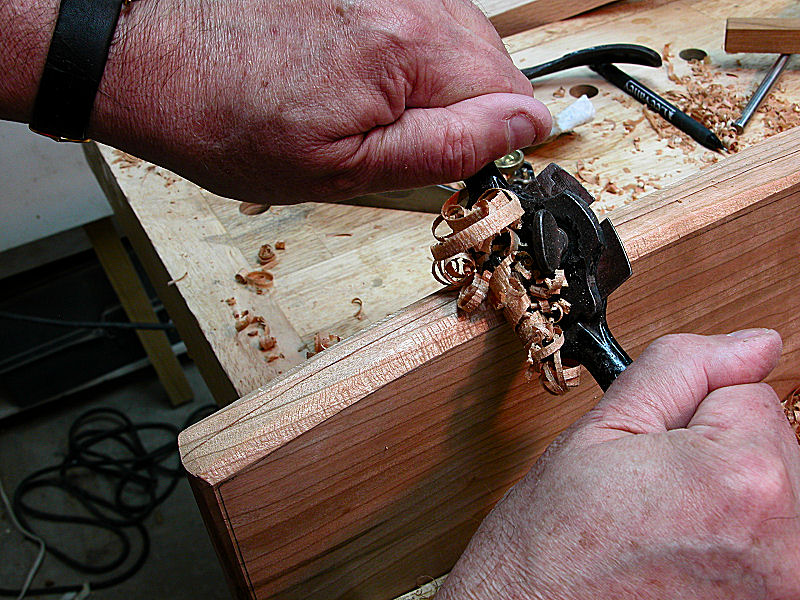

In the past I have written lovingly of my spokeshave. What a great little tool. That thing can sweeten up curves – both inside and outside – with no trouble. It can do a little bit of chamfering work. Heck, a sharp spokeshave is just plain handy to have around.

Note the key word in that last sentence – SHARP. That’s where I – and many other woodworkers – have trouble. You see, the iron on the spokeshave is just so short, it’s not easy to get a good grip on the sucker. I tend to scrape my knuckles against the sharpening medium as much as the blade bevel. And, after working the blade for a while, I tend to cramp up.

What I needed was a way to hold the blade more comfortably while getting a precise honing on the bevel. It may seem like a no-brainer to just put the blade into a sharpening jig and have at it, but there’s a problem with that – most side-gripping jigs can’t get a good purchase on the short spokeshave blade. And, holding the blade at a consistent angle is pretty darned important.

One low-cost solutions I have seen is to tape the spokeshave blade to a larger plane iron using duct tape, and then using that larger surface to get a better grip for either freehand or jig-based sharpening. It’s a pretty clever way to use what’s at hand, and, if you aren’t using the blade that often, it will certainly work for you.

There are other methods to secure such short blades. For instance, Lee Valley offers a short blade holder that uses magnets and a stop block to secure shorter blade for sharpening.

On my Tormek, a multi-purpose flat tool rest fills the bill for short blades. It’s a simple matter to adjust the platform on the guide bars to get the right angle, and it creates a solid base to rest the blade on while doing the honing. Quick. Easy. Back to work. Gotta like it.

While sharpening spokeshave blades can be a bit of a hassle, there are definitely opportunities to make the job a lot less onerous. Which, of course, leads to more time at the bench. And, isn’t that what we are all here for anyway?

I went the worksharp route for the machining of chisels and planes … and once I started using my Shapton Stones was game over.

I only use the machine to clean up damaged edges (so far only chisels and a damaged drawknife a friend gave me).

That Tormek sure is versatile, and handy to have around.