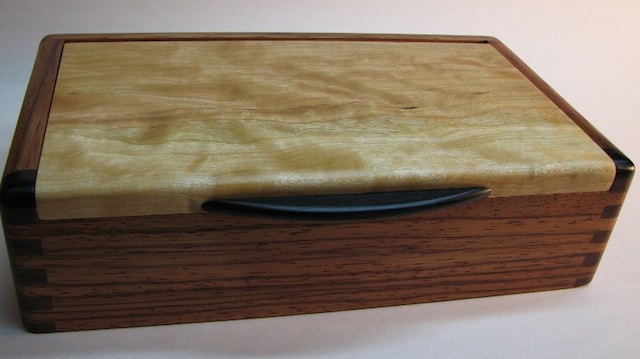

When it comes to most carbide router bits, you typically have a body and a pair of cutters that mimic the shape of the body of the bit. From a basic straight cutting bit to the most elaborate molding bit, it’s easy to see what I mean. The cutter does the cutting, while the body backs up the cut and prevents the board from overfeeding. For some bits, you can throw in a bearing guide and you are in business.

But, there is a class of bits that break this mold, and they have a ton of different uses. These bits look a lot like drill bits, but, believe me, they are entirely different animals that you won’t want to use in your drill press!

Spiral bits, as the name says, are indeed shaped like stubby drill bits. Unlike drill bits, which do their cutting at the tip, the leading edges of the flutes do the cutting, which means that the router bit will cut as you move it along the workpiece side to side.

These bits basically cut the same type of profile that a straight bit can make, but that’s like saying that a tricked out Ducati motorcycle is the same as a rusty, single speed beach cruising bike… Sure, they do, but the spirals can do so much more – with so much more style.

For instance, spiral bits can direct the cutting action and the resulting chips exactly where you want them to go. Think about cutting a mortise with a straight cutting bit. Sure, when you plunge the bit into the hole, it will bore in. But, the shavings that the bit makes can get packed into the hole, creating friction that can break down that carbide edge. An up-spiral bit, on the other hand, not only plows the hole, but it directs the chips out of the hole, clearing a path and preventing that packed-in feel.

Now, if you wanted trim the edge of a board with a straight cutter, you might get some splintering and tearout on the top of the board, but with a down-spiral bit, it pushes the fibers down toward the surface of the board, preventing that fraying on top.

So, you say you need BOTH faces to be clean? No problem, there are even combination up/down-spiral bits that can make both faces look their best. These are awesome when paired with a bearing guide for pattern routing… Perfect edges every time.

And, how about those edges? While straight bits can do a great job routing along edges, they can leave small scallops, similar to the milling marks you would see on the face of a board after it goes through a planer. Because the spiral bits cut with a shearing action, the surface is super smooth.

Hey, I love my straight cutting bits as much as the next guy, but when the situation is right, my head totally spins for a spiral bit!