I remember my first table saw. It was a Delta benchtop model that made all kinds of noise, had a 12 inch rip capacity and could barely hold a setting. I built some projects with it, and it was a definite step up from trying to cut everything with a circular saw.

Once I reached the capacity of that saw (which took no time at all), I stepped up to the saw I have – my Ridgid 3612. It has been my trusty companion for the past 14 years, and we have built a ton of projects together. I’ve ripped and crosscut with it. Cut box joints. Dadoes and grooves. We’ve been inseparable, and it works well in my shop.

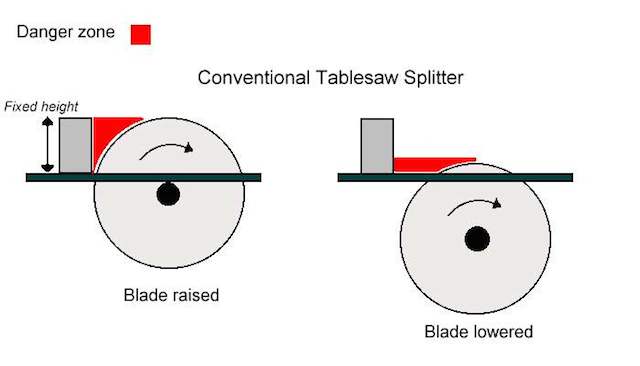

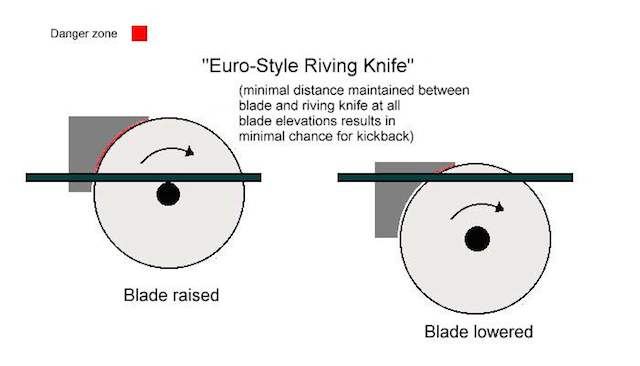

I’m beginning to wonder, however, if perhaps it might be time to upgrade the saw. There are some features of the saw that definitely mark it as dated. For instance, it has an old-style splitter instead of a riving knife. While I haven’t had a lot of issues with kickback, it has happened. I know that the new style riving knife design shortens the distance between the back edge of the blade and the splitter, reducing the likelihood that a kickback will happen. Plus, the fact that the riving knife rises and falls with the blade means that I can leave it in for non-through cuts (grooves and the like), meaning it will spend less time off the saw.

The newer saws also have shied away from the old-style open contractor style bases. My 3612 is wide open, and it took some wrangling to fit a dust chute onto the saw to control the dust that falls out from the cuts. The motor also sits out of the back, leaving a gaping hole where dust can still pour out from. Newer designs – known as hybrid saws – have enclosed cabinets and much better dust collection, meaning less vacuuming after a session with the saw. Plus, with the motor inside the footprint of the saw’s cabinet, I can wheel the saw closer to my bench to serve as an outfeed table.

So, I’m looking. The saw will definitely have to have a mobile base – that’s non-negotiable. And, it has to be able to spin a dado stack, which eliminates many of the portable jobsite saws. I also don’t think I need to go to 220 volts for the saw. That would make for a pretty expensive wiring job, and I have been managing with a 110 volt model for the past 14 years with few issues.

Honestly, I am looking very closely at another Ridgid saw. The current offering, the R4512, is a hybrid model complete with a mobile base, excellent dust collection and some very good reviews. However, I have looked at a few other models. I’m not sure where this is going to take me, or if I will even pull the trigger after doing a more thorough evaluation, but I will certainly be doing my homework on this one.

After all, I plan on getting at least another 14 years out of this sucker!