The first time I rode a bike. The first time I drove. My first date. The first night I spent away from home at college.

You really never forget your first time doing something memorable. And, yes, I am about to experience a new first.. my first 2 x 4 contest with the St. Petersburg Woodcrafter’s Guild.

I know. “Tom,” you must be thinking,”How on Earth are you going to contain your excitement?” Easy there, Sparky. It’s a big deal, but not a life changer.

The real challenge with a 2 x 4 contest is coming up with something inspired. I mean, there’s only so much inspiration you can get from looking at an eight foot long piece of construction lumber. Well, maybe you can envision a room being studded out in your home… but a furniture project? Hmm….

So, I tottered over to the local big blue home improvement center and saw the stack of 2 x 4s to pick from. They all seemed to look the same to me.

But, just as all the dogs look the same at first glance when you go to the kennel to get a new pet, a little bit of looking around will help you find the differences between the tail-wagging future four legged friends. After sifting through the pile, I found one that caught my eye. Very straight, just a few knots and not containing the pith of the tree.

OK, this one looks nice. Into the car with you!

Now, to think up a little inspiration… think.. think…think… A quick internet search shows some clever ideas out there floating around, and each of them is positively imaginative. Tables. Toolboxes. Toys. And boxes. Lots and lots of boxes.

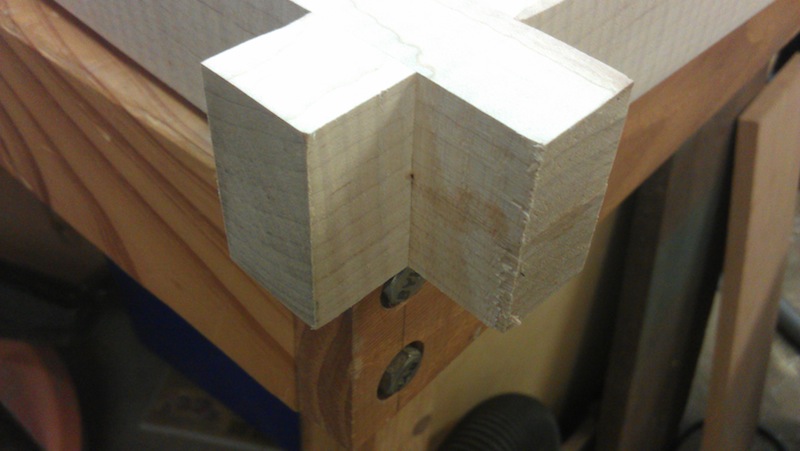

Wait a minute. What about a little box? Maybe built with a technique I haven’t yet tried before? A small box built like a pirate’s chest.. with a domed lid. I mean, even if the thing falls flat on its face, I am only out the $2.50 I spent on one stud. A few minutes with some pencil and paper and voila…

I can see this thing with some dovetailed sides, a coopered top and an inset bottom. Maybe I can even cut a fakie keyhole in the front to look like a lock goes there. I know if I am going to build this, I had better get a jump on the building.. since the meeting is June 25 – giving me a little less than a week to work on it.

Guess I know what I will be working on this weekend!