So, did anyone happen to hear about a big football game that happened last night?

Rumor has it that there was some big play at the end of the game that determined the outcome. Maybe I should pay better attention to these things…

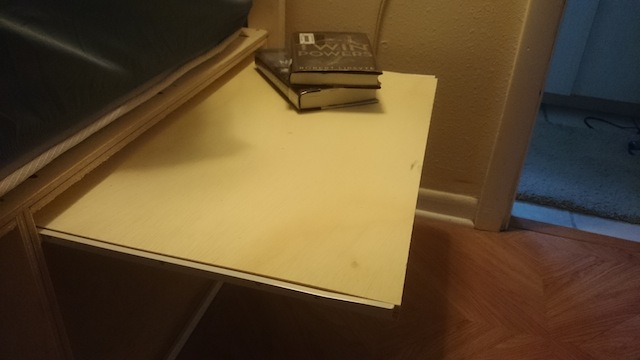

Part of the reason why I wasn’t into the big game was that I was busy pushing to the last parts of the bed project. Yes, my sinus/double ear/bronchitis issue slowed me down, so this weekend, I had to finish the last of the drawers. It took some time, but each of the drawers was relatively easy to finish, and they all roll like a dream on the 3/4 extension hardware that I picked up for the project.

Now that they are all in, the next step is to create the drawer fronts that will cover these drawer boxes and unify the sides of the bed. Since these cabinets are built without face frames, it’s going to be critical that I get everything lined up nicely so the fronts look balanced. The added bonus is that they will also serve as drawer stops, preventing me from pushing the drawers in too deep.

After that, I will need to put the finish on this project. Again, I am going with some water based finish, which should make this look pretty sweet and limit the amount of fumes in the house.

And, I had better get that done soon, because the wood for the next project has already arrived. What will it be? I can’t tell you, but I know that there is a young lady who will be expecting it sometime in the not too distant future!