I love jigs – they make your tool collection work faster, more efficiently and with a much greater versatility.

And, there are very few jigs as useful – and as easy to use – as the bench hook.

Yes, it’s a very classic, old-fashioned style jig, and it works primarily with hand tools – saws and hand planes. It makes many different shop tasks much easier and more effective. And, it’s insanely easy to build.

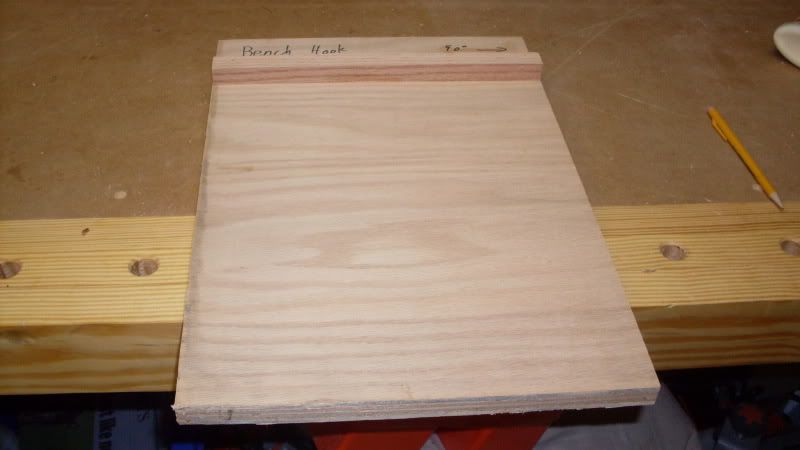

I built mine out of a piece of 3/4″ plywood – a piece about 12″ by 20″. It was a leftover piece of very high quality red oak veneer plywood from a previous project, trimmed perfectly square. There are also two sticks cut from larger pieces of a red oak board – 3/4″ square.

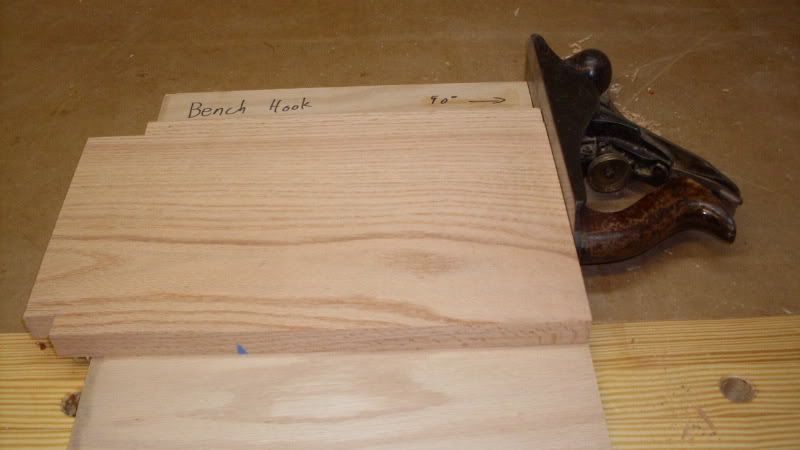

First of all, you want to glue and brad a piece of the board perpendicular to a square edge of the plywood. It’s OK to let this piece run long. Flip the board over and drive three or four screws into the piece from below to add more support for the piece. Once it’s secured, take the piece of plywood and the attached stick to your table saw and trim the stick flush with the edge of the plywood. For righties, make sure to trim flush on the right side, lefties need to make sure it’s flush on the left.

The next step is to glue and brad another piece of wood on the bottom of the plywood on the opposite edge. This piece should be a little shorter than the width of the plywood, but still installed perpendicular to the edge of the plywood. This piece becomes the stop which will rest on the edge of the bench.

That’s it. No. Really. You can stop there.

Now, how do you use the bench hook? Well, it’s a piece of cake. First, if you are going to cut small pieces of wood or do some hand cut joinery – such as hand cutting a tenon, you can simply brace the piece against the fence and cut away. This is a far easier way to cut than by securing the piece in a vise, cutting, releasing the vise, repositioning the work, tightening down the vise and doing it all over again.

Another neat use for the bench hook is to use it as a shooting board. If you want to sweeten up a joint, use a shoulder plane to trim a tenon’s width or ensure a board it cut squarely, you can brace the piece against the stop and plane. Pushing the plane to trim the work again pushes the work into the stop, making it secure without having to fix it into a vise.

Great jig. I’m planning to make one for my workbench this week. Googling for nice plan.