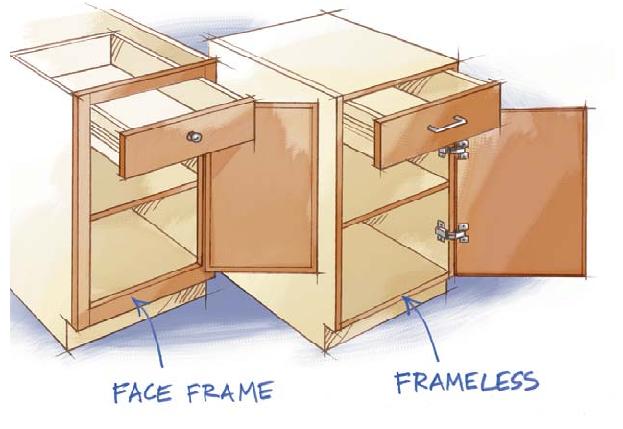

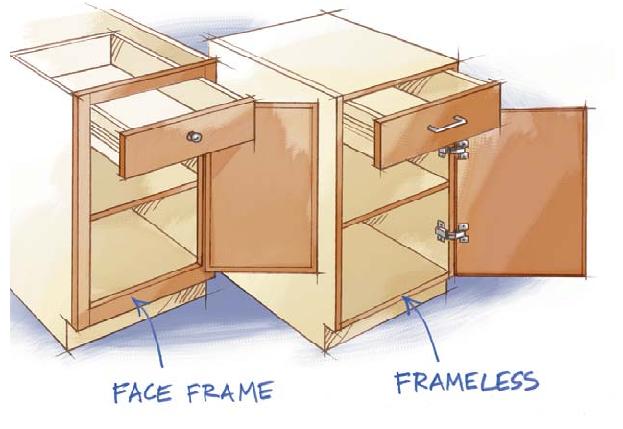

As you may have guessed from yesterday’s plan of the week, the bed I am building is basically a pair of frameless cabinets. This means that unlike North American cabinetry, there are no face frames, meaning that the drawer faces have to cover the openings and dividers between the drawer cabinets.

It’s not a better system. It’s not a worse system. It’s just different, and just as with face frame cabinetry, it poses a set of unique challenges that need to be overcome.

So, I started out making a story stick. Basically, you have to start with some quality measurements, and there’s no way to get more accurate ones than by taking direct measurements. I had attached a strip of plywood to the bottom of the cabinet faces before I placed them in the room, so I accounted for that in addition to the other strips and pieces I had to cut.

Using the story stick, I set up the table saw fence so I was absolutely positive that I was going to be on the money when it came time to cut. Again, instead of remembering fractional measurements, I used the exact measurements, making this brainless.

Another handy little trick I used to ensure that everything was going to work was I picked up a bag of 1/8″ tile spacers at my local home improvement center. Since the kerf on a full-sized blade is exactly 1/8″, using these spacers allowed me to throw away the tape measure and ensure that everything was spaced properly when I did the layout. Why didn’t I think about doing this years ago?

One I cut the top strip free from the piece of plywood I was using for drawer faces, I was able to use the spacers to properly align the top strip and attach it using pocket screws, and measure out the drawer faces. They were easy to mark out by simply tilting the entire piece out toward me and using the cubby dividers to mark where everything had to go.

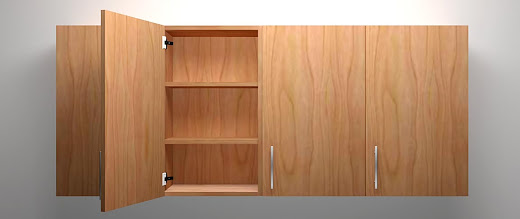

After I cut the pieces for each drawer free, I simply went back and screwed them in place. As you can see, I didn’t go for pulls for the drawers. Instead, I used a pattern I had built a long time ago to cut out handles on another project, and went that route to allow for the drawers to be opened and closed. Why? Well, Rhonda asked me if I was absolutely, positively sure that no one would ever bang his or her leg against a handle in the middle of the night.

Good point.

Now, all that’s left to do is a little bit of sanding, some finishing and a whole butt load of gloating. I think this one is just about done!