A router without bits is an interesting paperweight. A car without fuel in it is a nice piece of modern sculpture.

And, a hand plane without an iron is nice to look at, but that’s about it.

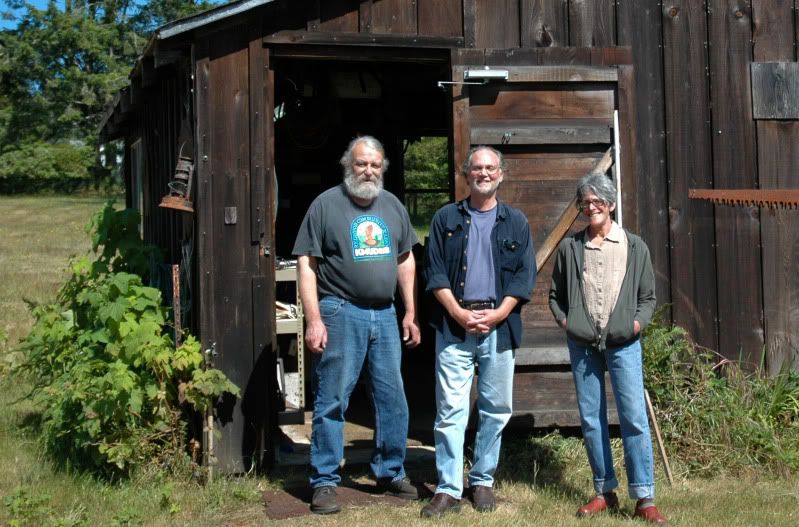

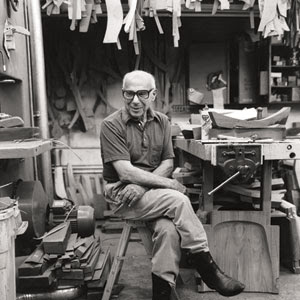

That’s why Ron Hock of Fort Bragg, California does what he does today. You see, Ron makes some of the world’s best plane irons for some of the world’s best woodworkers.

It all started back in 1981 when Ron, a budding knife maker, got his start the same month James Krenov opened his classroom at the College of the Redwoods. “Even though we were new to the area it was not difficult to feel an excited buzz in the community over the fact that the College of the Redwoods would be hosting his Fine Woodworking Program here.”

While Ron’s fame was made as the plane iron maker to Mr. Krenov, it was actually a different instructor and his student who first approached Ron for plane irons. After what Ron describes as a less-than-perfect first batch of irons, he refined his methods and the iron forms. Today, woodworkers can buy the same basic design as that second batch made way back in 1981.

Ron made it clear to me that he doesn’t forge his irons. “No sir, we’re not blacksmiths. We are machinists.” Using World War II era technology and vintage equipment, Ron and his associates follow the simple formula to success. First, the bar stock is sawn to size, slots are milled, bevels are ground and the maker’s logo is stamped. These raw irons get sent out for heat treatment and, once they come back, they are wire brushed to get the chalky oxide layer off. The bevels are reground and they are coated with a rust resistant oil. “This is not rocket science,” Ron joked.

While many of the irons are made in Hock Tools’ California shop, most others are made at a French facility which uses the latest technology. “Now, they use all the latest high-tech machinery: computer controlled lasers and grinders, cryogenic treatment. Even laser-etching the logo. In many ways, that IS rocket science!”

While there are many steel alloys out there, Ron’s irons come in two ‘flavors’ – O1 and A2. The O1 alloy is your basic high-carbon steel as was used decades ago. The addition of a pinch of manganese allows the blade to quench in oil, not water. A2 has added chromium, which makes the steel much tougher. The O1 blades are easier to sharpen, the A2 blades hold a honed edge longer.

While Ron does make replacement irons, the real fun comes when woodworkers want to build their own planes. From the early days of Mr. Krenov making his own planes, the hand-made movement has gathered a tremendous amount of steam. There are scores of simple plans for woodworkers to construct a custom plane to suit their purposes. The choice of woods for the plane body is tremendous, and Hock Tools offers plane irons for just this purpose. Ron often gets pictures of completed planes where the woodworker’s pride and enthusiasm is easy to see. “These are certainly exciting times to be a tool maker.”

While you think Ron would be satisfied keeping to the plane irons he does best, he has actually stretched into a new field of interest – shellac. “My brother-in-law owns a paint company. His sons who worked there at the time asked, ‘Hey Uncle Ron, what about some wood finishing products with your name on them?’ To which I said, ‘Got shellac?’”

Ron says that shellac is a wonderful finish that is more intriguing the more you learn about it. It’s non-toxic, easy to apply, easy to repair, and it’s one of very few insect products that we humans routinely use. Shellac is extremely useful old-fashioned stuff and an entertaining adjunct to the old-fashioned tools he makes. “I like to say, ‘With shellac, we’ve taken another giant step back…’”

While Ron’s website is a valuable source of information about planecraft, it’s not the only place you will be able to read all about it. “I’ve just finished writing a book on sharpening for Popular Woodworking Books: The Perfect Edge is due out this fall. It’s heavy on theory and metallurgy, lots about heat treatment and rust. Abrasives, too: what they are and which one does what best, etc. I’ve found woodworkers to be eager for information about all aspects of their craft and there are very few woodworking operations that don’t include a piece of steel somewhere between the worker and the wood. A better understanding of that piece of steel can’t be a bad thing so I’ve included as much as I could about the metal side of woodworking, along with the how-to sections for the various edges in the shop.”

While making high-quality plane irons has its challenges, Ron is very happy to have landed where he has. “I am so fortunate to have fallen into this industry. Not just that I happened along at the exact right time but that it’s this industry. Woodworkers are the friendliest, most interesting, decent people and I can’t tell you how grateful I am to find myself doing what I do and dealing with the kind of people I deal with. You’re the best part of what I do. You keep up the good work and I’ll do my best to do the same.”

The woodworking world is certainly more interesting and entertaining with Ron Hock around…

Woodworking Spotlight: Ron Hock

A router without bits is an interesting paperweight. A car without fuel in it is a nice piece of modern sculpture.

And, a hand plane without an iron is nice to look at, but that’s about it.

That’s why Ron Hock of Fort Bragg, California does what he does today. You see, Ron makes some of the world’s best plane irons for some of the world’s best woodworkers.

It all started back in 1981 when Ron, a budding knife maker, got his start the same month James Krenov opened his classroom at the College of the Redwoods. “Even though we were new to the area it was not difficult to feel an excited buzz in the community over the fact that the College of the Redwoods would be hosting his Fine Woodworking Program here.”

While Ron’s fame was made as the plane iron maker to Mr. Krenov, it was actually a different instructor and his student who first approached Ron for plane irons. After what Ron describes as a less-than-perfect first batch of irons, he refined his methods and the iron forms. Today, woodworkers can buy the same basic design as that second batch made way back in 1981.

Ron made it clear to me that he doesn’t forge his irons. “No sir, we’re not blacksmiths. We are machinists.” Using World War II era technology and vintage equipment, Ron and his associates follow the simple formula to success. First, the bar stock is sawn to size, slots are milled, bevels are ground and the maker’s logo is stamped. These raw irons get sent out for heat treatment and, once they come back, they are wire brushed to get the chalky oxide layer off. The bevels are reground and they are coated with a rust resistant oil. “This is not rocket science,” Ron joked.

While many of the irons are made in Hock Tools’ California shop, most others are made at a French facility which uses the latest technology. “They use all the latest high-tech machinery: computer controlled lasers and grinders, cryogenic treatment. Even laser-etching the logo. In many ways, that IS rocket science!”

While there are many steel alloys out there, Ron’s irons come in two ‘flavors’ – O1 and A2. The O1 alloy is your basic high-carbon steel as was used decades ago. The addition of a pinch of manganese allows the blade to quench in oil, not water. A2 has added chromium, which makes the steel much tougher. The O1 blades are easier to sharpen, the A2 blades hold a honed edge longer.

While Ron does make replacement irons, the real fun comes when woodworkers want to build their own planes. From the early days of Mr. Krenov making his own planes, the hand-made movement has gathered a tremendous amount of steam. There are scores of simple plans for woodworkers to construct a custom plane to suit their purposes. The choice of woods for the plane body is tremendous, and Hock Tools offers plane irons for just this purpose. Ron often gets pictures of completed planes where the woodworker’s pride and enthusiasm is easy to see. “These are certainly exciting times to be a tool maker.”

While you think Ron would be satisfied keeping to the plane irons he does best, he has actually stretched into a new field of interest – shellac. “My brother-in-law owns a paint company. His sons who worked there at the time asked, ‘Hey Uncle Ron, what about some wood finishing products with your name on them?’ To which I said, ‘Got shellac?’”

Ron says that shellac is a wonderful finish that is more intriguing the more you learn about it. It’s non-toxic, easy to apply, easy to repair, and it’s one of very few insect products that we humans routinely use. Shellac is extremely useful old-fashioned stuff and an entertaining adjunct to the old-fashioned tools he makes. “I like to say, ‘With shellac, we’ve taken another giant step back…’”

While Ron’s website (hocktools.com) is a valuable source of information about planecraft, it’s not the only place you will be able to read all about it. “I’ve just finished writing a book on sharpening for Popular Woodworking Books: The Perfect Edge is due out this fall. It’s heavy on theory and metallurgy, lots about heat treatment and rust. Abrasives, too: what they are and which one does what best, etc. I’ve found woodworkers to be eager for information about all aspects of their craft and there are very few woodworking operations that don’t include a piece of steel somewhere between the worker and the wood. A better understanding of that piece of steel can’t be a bad thing so I’ve included as much as I could about the metal side of woodworking, along with the how-to sections for the various edges in the shop.”

While making high-quality plane irons has its challenges, Ron is very happy to have landed where he has. “I am so fortunate to have fallen into this industry. Not just that I happened along at the exact right time but that it’s this industry. Woodworkers are the friendliest, most interesting, decent people and I can’t tell you how grateful I am to find myself doing what I do and dealing with the kind of people I deal with. You’re the best part of what I do. You keep up the good work and I’ll do my best to do the same.”

The woodworking world is certainly more interesting and entertaining with Ron Hock around…

The incessant clatter of students taking typing classes has been replaced by the more muffled sound of computer keyboarding. Many schools have abandoned ordered rows of students for a more collaborative ‘working group’ arrangement.

The incessant clatter of students taking typing classes has been replaced by the more muffled sound of computer keyboarding. Many schools have abandoned ordered rows of students for a more collaborative ‘working group’ arrangement. “Many of the students in my classes have never used a woodworking tool in their lives,” said Paul. “Giving them the skills they need to overcome their fears and inexperience is a liberating experience for them. Many of the students are so energized by the process, they actually become shop assistants, shepherding their classmates forward.”

“Many of the students in my classes have never used a woodworking tool in their lives,” said Paul. “Giving them the skills they need to overcome their fears and inexperience is a liberating experience for them. Many of the students are so energized by the process, they actually become shop assistants, shepherding their classmates forward.”

However, on the island of

However, on the island of  Roe builds both decorative (known as shelf decoys) and working decoys. Surprisingly, there is very little difference between the two. “The carving is the same for both. The main difference is in balancing it up so the decoy will float properly. I normally hollow out the working decoy and sometimes the keel so I can add melted lead to make it float level when it hits the water. It takes some time to get it right, but it’s something that makes the decoys a pleasure to use.” Roe was eager to point out that when you throw a decoy into the water in the early morning darkness, it’s comforting to know it will float properly and not require any nocturnal maneuvers to right it.

Roe builds both decorative (known as shelf decoys) and working decoys. Surprisingly, there is very little difference between the two. “The carving is the same for both. The main difference is in balancing it up so the decoy will float properly. I normally hollow out the working decoy and sometimes the keel so I can add melted lead to make it float level when it hits the water. It takes some time to get it right, but it’s something that makes the decoys a pleasure to use.” Roe was eager to point out that when you throw a decoy into the water in the early morning darkness, it’s comforting to know it will float properly and not require any nocturnal maneuvers to right it. Just how many decoys does Roe make annually? “I average nearly 300 birds a year. I do most of the band saw work in the winter when it’s cooler in my saw room. Then, it takes a few months to chop out the bodies and then another month or so carving out the heads. Finally, it’s sanding, undercoating and paint, paint, paint.” When I spoke with Roe over the phone, he was busy painting about a dozen of his decoys.

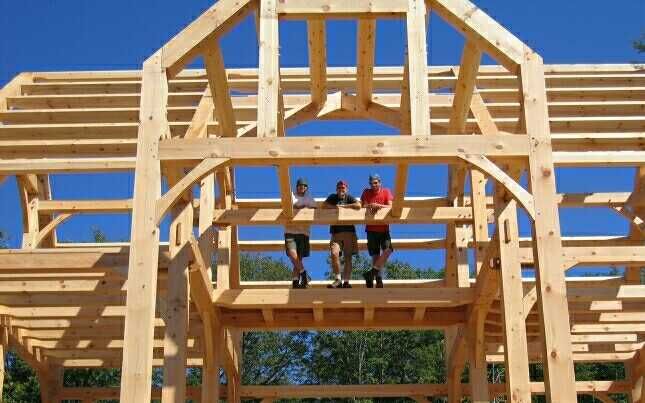

Just how many decoys does Roe make annually? “I average nearly 300 birds a year. I do most of the band saw work in the winter when it’s cooler in my saw room. Then, it takes a few months to chop out the bodies and then another month or so carving out the heads. Finally, it’s sanding, undercoating and paint, paint, paint.” When I spoke with Roe over the phone, he was busy painting about a dozen of his decoys. But, then you may come across an exception to the rule. There are homes out there being assembled out of large timbers. These buildings have soaring, graceful hand-carved timbers from the floor to the roof line defining an open, comfortable living area. Traditional timber framing, while not the most common construction method, is alive and well and being taught to a new generation of woodworkers.

But, then you may come across an exception to the rule. There are homes out there being assembled out of large timbers. These buildings have soaring, graceful hand-carved timbers from the floor to the roof line defining an open, comfortable living area. Traditional timber framing, while not the most common construction method, is alive and well and being taught to a new generation of woodworkers. Clark Bremer, the owner of

Clark Bremer, the owner of  Not only competitive, but green as well. “Modern timber frames are often enclosed with structural insulated panels, which are applied to the outside of the frame. This creates an unbroken blanket of insulation around the house, which is extremely energy efficient. And like the timber frame itself, the panels are pre-cut in the shop before being brought to the site, making installation very easy for a trained timber framer to install. In a moderate sized home, the frame can be erected and enclosed in panels in 1-2 weeks, minimizing the risk of a weather delay.”

Not only competitive, but green as well. “Modern timber frames are often enclosed with structural insulated panels, which are applied to the outside of the frame. This creates an unbroken blanket of insulation around the house, which is extremely energy efficient. And like the timber frame itself, the panels are pre-cut in the shop before being brought to the site, making installation very easy for a trained timber framer to install. In a moderate sized home, the frame can be erected and enclosed in panels in 1-2 weeks, minimizing the risk of a weather delay.” It’s true that timber framing looks complex and on a massive scale, but once the individual elements are broken down, it’s not that difficult for any woodworker to master. “This is mortise and tenon joinery, after all, and woodworkers all know the precision required to make that look good.”

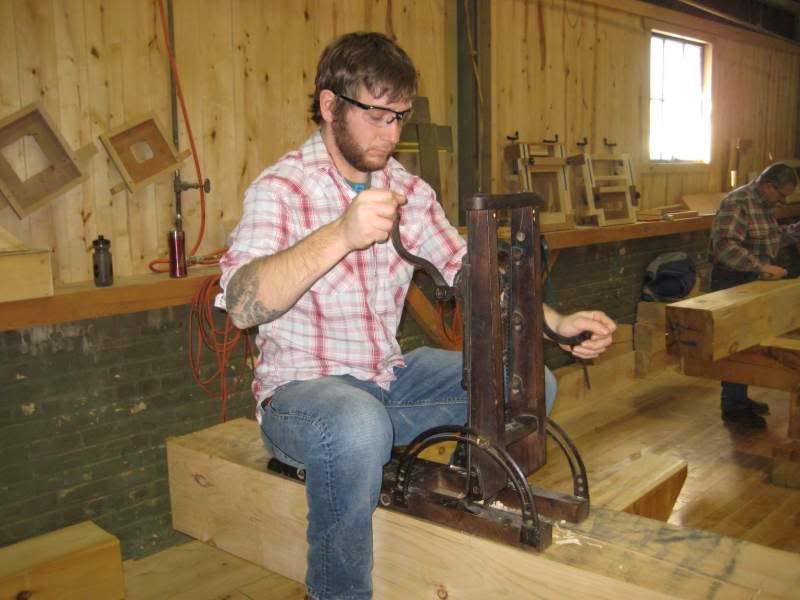

It’s true that timber framing looks complex and on a massive scale, but once the individual elements are broken down, it’s not that difficult for any woodworker to master. “This is mortise and tenon joinery, after all, and woodworkers all know the precision required to make that look good.” And then there are the tools. At Clark’s shop, he and his crew work extensively with hand tools. This carries through to his teaching methods as well. “Sure, there are CNC machines that can cut entire timbers, but these machines are very expensive, and they do not have the hands and eyes of a craftsman, who can read the grain, avoid tear out, and feel pride in the quality of their work. That’s why we love antique tools, and take the time to send them through “rehab” and get them back into a productive life. We use chisels, hand planes, slicks and draw knives every day. I also have an old hand-crank boring machine that we bring out for classes and demonstrations.”

And then there are the tools. At Clark’s shop, he and his crew work extensively with hand tools. This carries through to his teaching methods as well. “Sure, there are CNC machines that can cut entire timbers, but these machines are very expensive, and they do not have the hands and eyes of a craftsman, who can read the grain, avoid tear out, and feel pride in the quality of their work. That’s why we love antique tools, and take the time to send them through “rehab” and get them back into a productive life. We use chisels, hand planes, slicks and draw knives every day. I also have an old hand-crank boring machine that we bring out for classes and demonstrations.”

According to Derek, “The tool has made woodworking a whole lot easier for beginning and advanced woodworkers alike. Sure, there may be some who prefer more traditional joints, but for building fast,strong, and easy, pocket screws are a great choice.”

According to Derek, “The tool has made woodworking a whole lot easier for beginning and advanced woodworkers alike. Sure, there may be some who prefer more traditional joints, but for building fast,strong, and easy, pocket screws are a great choice.” The variety of pocket hole cutting jigs offered by Kreg is pretty staggering. There are pneumatic, high-volume set ups for furniture factories all the way to the simplest single hole jigs offered for the handy DIYer. By far, their most popular model is the Kreg Jig Master System (model K3), the system favored by most woodworkers. Complete with set ups for semi-production and portable bases, the Master System is an improvement over the K2000, the former sales leader. “Even something as simple and elementary as moving the clamp handle to the front of the jig was a huge convenience for woodworkers. Now, instead of having to reach around the back of a large panel to secure the work piece, they can do it all from the front.”

The variety of pocket hole cutting jigs offered by Kreg is pretty staggering. There are pneumatic, high-volume set ups for furniture factories all the way to the simplest single hole jigs offered for the handy DIYer. By far, their most popular model is the Kreg Jig Master System (model K3), the system favored by most woodworkers. Complete with set ups for semi-production and portable bases, the Master System is an improvement over the K2000, the former sales leader. “Even something as simple and elementary as moving the clamp handle to the front of the jig was a huge convenience for woodworkers. Now, instead of having to reach around the back of a large panel to secure the work piece, they can do it all from the front.” And it’s not only pocket screws when it comes to Kreg. In 2003, the company started building a line of highly accurate (and well reviewed) fences and guides for band saws, router tables, miter saws, table saws and other shop tools. “So far, all of our precision guides, fences and jigs have all been met with broad support, and our customers have been very happy with what we’ve come up with.” Even more recently, Kreg has announced an entire line of Klamp System™ components designed to improve clamping around anyone’s shop and a family of Precision Routing products including the new Precision Router Table which includes a table saw style fence which self squares with the table’s miter slot.

And it’s not only pocket screws when it comes to Kreg. In 2003, the company started building a line of highly accurate (and well reviewed) fences and guides for band saws, router tables, miter saws, table saws and other shop tools. “So far, all of our precision guides, fences and jigs have all been met with broad support, and our customers have been very happy with what we’ve come up with.” Even more recently, Kreg has announced an entire line of Klamp System™ components designed to improve clamping around anyone’s shop and a family of Precision Routing products including the new Precision Router Table which includes a table saw style fence which self squares with the table’s miter slot. That’s why I like sensible clothes. Pants that are durable, shirts that fit and are comfortable and clothes that just don’t wear out when you are working hard.

That’s why I like sensible clothes. Pants that are durable, shirts that fit and are comfortable and clothes that just don’t wear out when you are working hard. Suzanne Harms, the company’s marketing director, said that it was important early on for Duluth Trading to reach out to woodworkers through the woodworking magazines. “Our brand and products are built around guys who thrive on the craftsmanship and challenge of working with their hands. Carpenters, woodworkers, cabinet makers, builders, remodelers, hobbyists, the guy building a deck, tinkers and gadget and gear heads, car enthusiasts, bikers, hobby farmers. As our business has grown rapidly in the last 8 years, we’re appealing to a broader range of hands-on men and women. And our focus is more clearly on designing apparel and gear that supports what Duluth customers do – and help them do what they do better and safer.”

Suzanne Harms, the company’s marketing director, said that it was important early on for Duluth Trading to reach out to woodworkers through the woodworking magazines. “Our brand and products are built around guys who thrive on the craftsmanship and challenge of working with their hands. Carpenters, woodworkers, cabinet makers, builders, remodelers, hobbyists, the guy building a deck, tinkers and gadget and gear heads, car enthusiasts, bikers, hobby farmers. As our business has grown rapidly in the last 8 years, we’re appealing to a broader range of hands-on men and women. And our focus is more clearly on designing apparel and gear that supports what Duluth customers do – and help them do what they do better and safer.” All of their clothing – from the signature

All of their clothing – from the signature  While their products very tough and useful, the Duluth Trading ad copywriters have a great deal of fun when describing and designing their products. One of the funniest and longest-lived ads deals with their extra long tail work t-shirts. They are advertised to cover the dreaded ‘plumber’s butt,’ and are sold in a small plastic pail marked

While their products very tough and useful, the Duluth Trading ad copywriters have a great deal of fun when describing and designing their products. One of the funniest and longest-lived ads deals with their extra long tail work t-shirts. They are advertised to cover the dreaded ‘plumber’s butt,’ and are sold in a small plastic pail marked