I have got to tell you, this Plan of the Week thing I have been doing the past few weeks has been pretty darned successful so far. I have had people send me plans they have drawn up. I have linked to popular plans from woodworking magazines. I have posted plans for several rooms in the house.

And, this past weekend, I posted a plan for a miter saw stand. OK, innocuous enough. But, it did elicit an interesting comment from one of my readers:

I’m a sucker for DIY as much as anyone else, but wouldn’t one of the prefab manufacturer’s stands be a lot lighter and just as good, for around the same price? They’re even included free with some of the higher-end mitre saws.

Now, that’s a great question that I don’t normally get on my blog. And, one that deserves a good answer.

Woodworking is a many-splendored thing, isn’t it? I mean, there are all levels by which one can get involved in the craft. There are those who love up-close, intricate work, while others love big, burly chairs and tables. There are turners, scrollers, carvers… the works.

Just as there are many different woodworking styles, there are also many different woodworking philosophies. I have heard of people who are collecting tools, and when they get enough to have a complete shop (table saw, jointer, planer, band saw, routers), then they will start woodworking. I have also seen (and, I am one) woodworkers who, given a jig saw, a drill and enough imagination, have leapt into woodworking with great gusto, building their skills and attempting to impress the heck of their families and friends.

Both approaches are perfectly fine and absolutely acceptable, as long as the woodworker is fine with that. Different strokes for different folks.

However, there are also those who, while they may buy a few tools, get a tremendous amount of joy out of building their own. Hand planes. Band saws. Drum sanders. If money is tight and the imagination of the woodworker is vast, there’s really no end to the number of tools that can be built. And, many of these tools work just as well – if not better – that the commercially-available ones.

For me, though, I don’t get a kick out of making my tools. Not in the least. So, when I get a chance to buy or inherit a tool, I usually go that route.

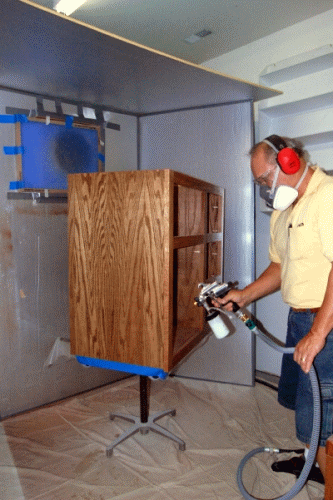

Now, if the tool needs a place to rest, I will go in and build the table, like I did a few years back when I built my miter bench. Woodworking magazines are seldom without a plan for a piece of shop furniture you can built to make things better for your work flow. Heck, I know woodworkers who build entire banks of shop storage cabinets to hone their skills before attempting something like a set of cabinets in their kitchen, just to prove they could do it.

Of course, there are also beautiful, heavy duty, hyper accurate items you can buy for your shop. I frequently drool at the diamond-plate shop cabinets available at the local home center and wonder what they would look like in my shop.

And, ultimately, couldn’t you just buy furniture and not build it?

So, I guess the answer is this… can you build something like a miter saw stand? You bet. Can you buy one? Absolutely. Is one better than the other?

Who am I to say?

Just make a decision that fits your budget, talents and needs, and you will be a happy woodworker.