Oak is – by far – one of the most plentiful North American hardwoods on the market. According to the American Hardwoods Council, oaks comprise nearly 51% of all hardwoods harvested and brought to market.

While this may seem very boring and redundant, there’s actually quite a bit of variety when it comes to these oaks. In fact, there are more than 600 species of trees worldwide which come from the genus Quercus. Some of the characteristics that may make each species stand out include bark thickness (for cork oaks), leaf shape, growth habits and whether or not the tree is evergreen or deciduous. Yes, in the very deep south, trees such as live oaks never drop all of the leaves in their canopies.

Fortunately, for woodworkers, things are a little less confusing when it comes to shopping for lumber. “While there are several commercial species, you can basically break the oaks down into two separate groups,” said Eric Proirier of Bell Forest Products. “It’s kind of like selecting a wine for dinner. You have your reds and your whites.”

It’s funny that Eric mentioned wine, because one way to tell the difference between red oaks and white oaks has a lot to do with how liquids pass through them. “Wine barrels – and ships, for that matter – are always made of white oak because liquids can’t pass through the pores of the wood. Very important if you are trying to age wine – or sail the high seas!”

Red oaks are exceptionally plentiful. In fact, 36% of all North American hardwoods brought to market are considered red oaks. White oaks, on the other hand, still make up a hefty 15% of the North American hardwood market, but are some of the most sought after boards out there. Why?

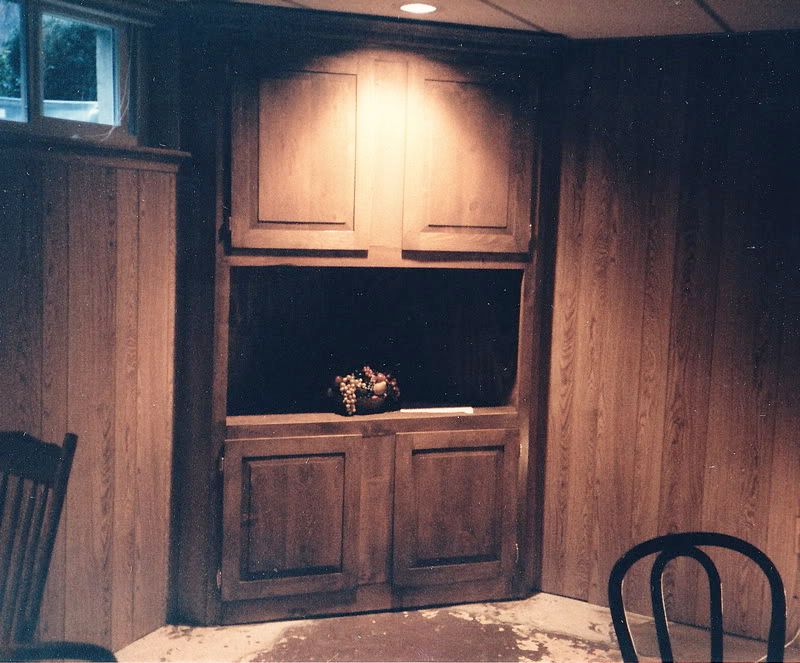

“The grain pattern on white oaks is typically finer than that of reds,” said Eric. “In many cases, this gives a more refined look to the piece, something woodworkers tend to look for while building projects.”

Another key difference between the two oaks comes to the ray flakes seen when the boards are quartersawn. “In quartersawn white oaks, the ray flake pattern is more pronounced. These rays are very pronounced in quartersawn wood, and are typically larger and more numerous in white oak.” Ray pattern, actually part of the grain of the wood, was highly sought after during the Arts and Crafts movement, with many handsome pieces made that highlighted the effect.

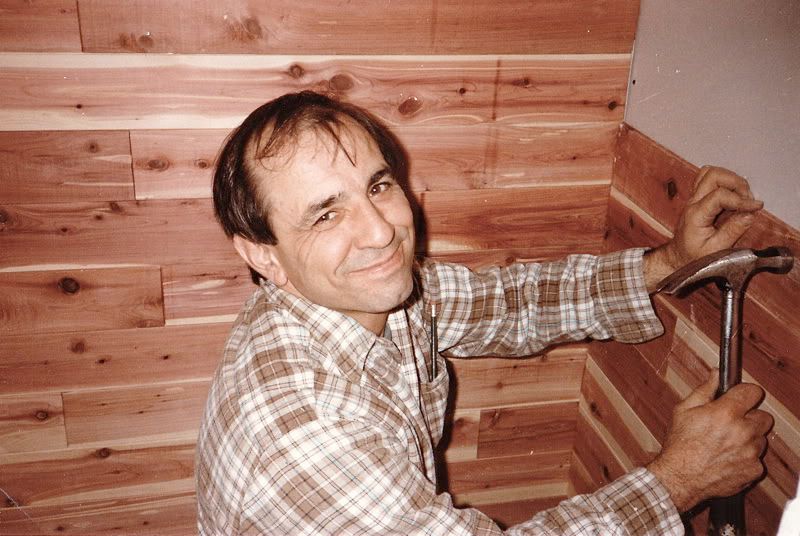

White oak is very hard and heavy and works very well. The tannins in the oak, however, can affect any steel fasteners used to build the piece, turning a dark black and staining the wood. “Brass screws used in pre-bored holes do better, or be sure to hide your fasteners under plugs to prevent some ugly looking stains.”

Another interesting characteristic about white oak is how it responds to ammonia fumes. “This is the wood that the Arts and Crafts masters used in their fuming tents. The wood looks great when finished like that, but remember that ammonia is pretty nasty stuff. If you aren’t 100% sure how to get that fumed finish safely, you might want to pass. When possible, we always recommend you use safer finishes.”

While white oaks are definitely beautiful, they aren’t necessarily superior to their red cousins. “White oaks don’t bend nearly as well as reds, and red oaks are plenty handsome on their own. Whichever oak you choose, you are very likely to be happy.”

But, for that classic Arts and Crafts looks, it’s hard to beat white oak.