My dad was fond of telling me to never discuss politics or religion with others. I thought this odd advice, but, once I tried it at college, I knew exactly why he told me. People tend to get very defensive if they feel their beliefs are attacked, and they will push like mad to have you think their way.

I guess my dad could have also added talking to people about their methods of sharpening. Woodworkers tend to find a way to do something – especially as important as their techniques for putting a keen edge on their chisels and plane irons – and stick with it.

Now, let me make myself clear before I start to ramble on here. Sharpening is a very broad term when it comes to edged tools. There are actually two distinct steps in the sharpening process. The first is grinding. That involves the rapid removal of material to shape a bevel and remove any damage to a cutting edge. There are many ways to do this, and you’ll see woodworkers rely on grinding wheels, very coarse abrasives and flat platen grinders to accomplish this task. While getting the edge ready to be honed is important, it’s not what I am going to cover.

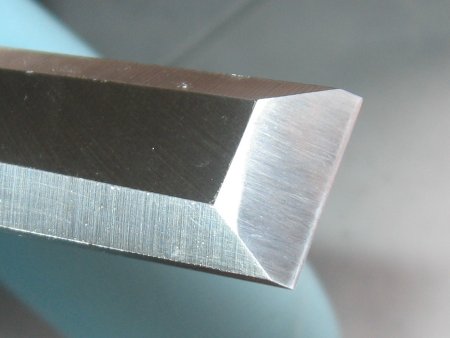

No, I’m talking about the act of honing… progressively removing small amounts of metal in order to achieve a fine cutting edge. This act is typically performed by hand using careful amounts of pressure with very fine abrasive agents. Here’s where the interesting discussions get started… and where you will see lots of folks start to take sides.

There are basically five different kinds of media on which people will hone their edges – oil stones, water stones, sandpaper, diamond stones or ceramic stones. Each has its boosters and each has its detractors. Some people will make authoritative claims that one method is far superior over the others – even if they have never used the other methods in question before. I’ve decided to at least give you a bit of a primer on the different methods and what I hear are the pros and cons of each.

Oil Stones: These stones are typically natural stones quarried from the Earth. They typically bear the name of the region from which they were harvested – for instance, a hard Arkansas stone is found in a mining area that falls near the Arkansas and Oklahoma border. There’s not a ‘grit measurement’ given for oil stones – their level of abrasive fineness is inferred from their descriptive name (Hard India, Translucent White Arkansas). Exceptionally hard, most oil stones do not need to be flattened with another stone for years of use. They use an oil-based lubricant to make sharpening easier and to clear the swarf – the metal shavings.

The agent that does the cutting for oil stones is novaculite, a silica based impurity that is found in these sedimentary rocks.

- Pros: The stone stays true longer, giving the best sharpening job. They have been used for thousands of years with great success. The oil helps prevent rust on the blades being sharpened. Lower cost compared to other methods.

- Cons: The stones can glaze with metal cuttings, making sharpening difficult. The hard stones sharpen slowly. Oil makes a mess.

Water Stones: Japanese woodworkers have been using these stones for hundreds of years with great success, and now the stones are now in western shops. Naturally quarried water stones are becoming more rare, so many of today’s are manufactured. The water stones are softer, which means they abrade more quickly, exposing fresh cutting media as the sharpening progresses. The water creates less of a mess to clean up and leaves no residue. The stones – especially the manufactured ones – are advertised by their grit size – a 1,000 grit medium stone. Because they do wear quickly, these stones do need to be flattened, or dressed, frequently to ensure blades and plane irons are sharpened squarely.

- Pros: Fast cutting. Only water is used with the stones. Easier to pick up the proper grit size. Most popular sharpening option, meaning more choices for buyers.

- Cons: Creates a mess. Water on steel – if not properly tended to – can lead to rust. The stones need extra care to ensure they remain flat. The price can get high for high-quality stones.

Scary Sharp (Sandpaper): At first, you may think this is some kind of joke. Sandpaper as a medium to sharpen? You bet… Different grits of sandpaper (400, 600, 800, 1,000) can take an abused edge from butt ugly to razor sharp. The paper, which does the cutting, is typically adhered to a dead flat substrate, which means you you will always be working on a flat base. You can use a few squirts of something like WD-40 to help the blade glide over the surface, but it’s totally optional. Remember, you are sharpening on the sandpaper on top of the hard substrate… so there is the chance that your paper may move during sharpening, dubbing your edges.

- Pros: Cost – it’s dirt cheap to get stared on. The sandpaper grits can be found at a home center or auto parts store. The paper cuts aggressively, even at higher grits.

- Cons: Cost – you will be buying packages of sandpaper forever to keep sharpening, and the durability of the sandpaper is limited. You could dub your edges if not careful, meaning that you won’t have sharp edges.

Diamond Stones: Diamonds are a girl’s – and a woodworker’s – best friend. As the hardest substance known to science, industrial grade monocrystalline (on premium stones) or polycrystalline diamonds (on cheaper stones) can abrade away metal very quickly. The tiny diamonds are embedded on a flat metal plate with a nickle-based metallic binder, and many have ‘holes’ in the metal plate to allow the swarf a place to go. Diamond stones are used with a squirt of water to allow for lubrication and swarf removal. These are some of the most expensive stones out there.

- Pros: Diamond stones cut quickly. They need no care other than an cleaning and drying after use. They come in a variety of grits to accomplish a number of tasks. They are the only medium can can be used on carbide.

- Cons: Price. Conventional wisdom holds that the swarf generated by sharpening steel on a diamond stone will break the bond with the substrate. Cost.

Ceramic stones: The new kid on the block, ceramic stones are always manufactured. Basically, a ceramic mixture is carefully mixed with sharp cutting agent embedded within before it is fired. These stones can be used dry on blades, but they do need to be cleaned with a household abrasive cleaner. These stones can be quite pricey, but their quality is quite high and they can become lifetime stones for your tools. They are typically found only in finer grits, so if you do want to work an edge over, it could take some time to remove enough material.

- Pros: Insanely flat. Can be worked without water or oil. Very hard, durable surface that can’t dish.

- Cons: Cost. Can become glazed and needs maintenance to keep cutting medium clear.

What does this mean for the average woodworker? Well, each of these methods does provide outstanding results and can sharpen just about every tool in the woodworker’s arsenal. If you are using a method that gives you outstanding results, I say stick with it. In fact, if you are using several methods – say a diamond stone for coarser work and an oil stone for finer honing… there’s nothing wrong with that either.

However, I’m sure several readers will weigh in with their preferred method of sharpening. They will tell me that I am way off base and that their method is the only one that works – the others are just trash.

That’s what you get for talking politics, religion or honing!

Tom,

While I agree to stay away from Religion & Politics, I’m going to wade waist deep into honing.

I used to use a water stone for honing, with good results. I just hated the process.

At Woodworking in America I spent 45 minutes in the Lee Valley booth using their Veritas Mk.II Powered Sharpening System. I’ve since bought and received it. I tried it for the first time over the weekend and it took the new (not flat or sharp) blade in my Stanley #90 Rabbet Plane from junk to sharp in about 3 or 4 minutes. As they told me, the 9 nanometer (I think that’s the unit) grit paper is good enough to produce a perfect edge. For additional honing, I did pick up an extra platter and honing compound, I just haven’t had a chance to add suede to it yet.

So while the Mk.II is not cheap (almost $400.00) neither are a set of quality stones. In use the Mk.II is very easy to use and even more importantly, it is quick and clean. I’m happy I bought it.

Tom

I find woodworkers tend to worry too much about the type of stones they use – it is much more important to establish a sharpening regime which allows you to achieve repeatable results in a reasonably quick time. After all, sharpening isn’t “fun”, its just something we need to do! Understanding what you are trying to achieve when you sharpen an edge tool is important – woodworkers tend to obsess over numbers and angles.

So learn to get your tools sharp with whatever stones you have – and go make some shavings!

Hope this helps,

Philly