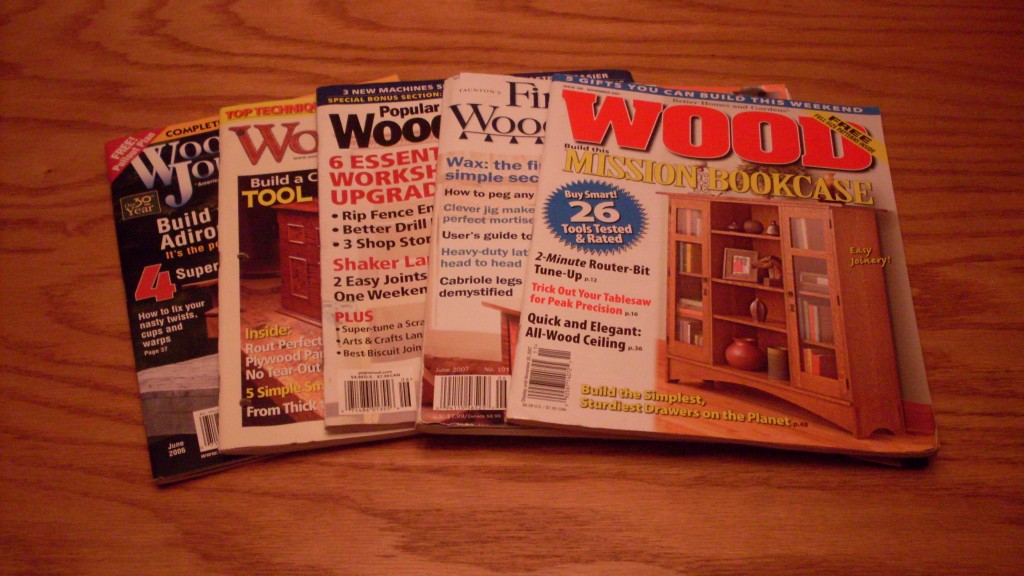

There are few sources of woodworking know-how as rich as the many woodworking magazines published around the world. From magazines that appeal to a wide woodworking audience to specialized titles that focus on one aspect of the craft, there’s something to suit every one’s woodworking needs.

Each edition is loaded with shop tips, projects, background articles and plans for easy-to-build jigs. The writers and editors have a great opportunity to strut their stuff and provide valuable information for their target audience. If you subscribe, this wisdom comes right to your mailbox as each edition rolls off the presses. Month after month.

Their strength – frequency of issue – can also be a weakness. After all, by the time you get a chance to read through the magazine, scheme in your mind what you would like to build and find the time to do it, the next edition is just about ready to ship. And, the process begins all over again.

This week, we want to know approximately how much do you build and incorporate from each edition of woodworking magazine you receive. Do you build everything you possibly can from each issue, or do you find yourself just trying to keep pace?

[poll id=”90″]