This coming weekend is the St. Petersburg Woodcrafters Guild annual picnic on the shores of beautiful Lake Seminole Park in central Pinellas County. Sure, it’s getting a little warm to be outdoors in Florida this time of the year, but there are still just enough cool breezes – and a cold front nearby – to keep the temperatures tolerable. Besides – it’s an excellent opportunity to get to eat a bunch of great food and hang out with other woodworkers. Oh, and I get to eat some Publix fried chicken… the local grocery chain makes the best stuff I have ever tasted. Oh, boy, is it ever good….

One of the activities for the big day will be a carving event. Last year, a few pieces of basswood were handed out with a few carving knives, and everyone at the event got to work. There were some beautiful carvings, and it was easy to quickly see how good some of us were, and how far many of us have to go to do a good job! But, that’s part of the fun of going to a woodworking picnic, right?

This year, I wanted to bring a knife I use in my shop. This is a Sloyd knife. My neighbor, originally from Sweden, told me that basically it is a craft knife that many Swedish woodworkers start off with as their first tool. It’s great for carving, slicing and other small shop tasks. I got mine a while back from a friend who saw it for sale in a shop up in New Jersey and sent it down to me. For years, it sat in my tool chest, just waiting for the day when I would use it.

As with most blades, it came from the store ground nicely, but needing a honing to really make it special. I have tried sharpening it by hand, but that can be tough on the fingers. The knife jig that came with my Tormek was available as well, but it never was able to get a good purchase on the blade – it was just too small.

That’s why I was pleased to get the newest jig from Tormek. The new small knife jig is a clever piece of tooling that had me honing in very little time. It basically consists of two parts – a cross bar of metal that gets clamped into the jaws of the jig’s knife blade, and a plastic clamp that works by grabbing the handle of the knife.

First, I set the cross bar of the jig into the jaws of the knife jig blade. It’s critical that you get this crosspiece aligned parallel with those jaws. This makes the next step a whole lot easier. Fortunately, if you flush up the front of that crossbar with the front edges of the jig, you are in the butter zone.

The next step is to clamp the knife handle into the plastic clamp. There is a screw clamp knob on the back of the jig that allows this to grab knife handles of many different shapes and sizes. Since the Sloyd knife I am using has a wonderfully contoured grip, it took a little finessing to find the sweet spot to clamp it in place. But, once it was there, the blade was parallel with the rest of the set up and it was ready to go onto the sharpener.

It was a simple matter to run the blade over the sharpening wheel on the first side, then flip everything over and move to the second. Since this is a dual bevel took – not a single like a chisel or plane iron – I had to make sure I had everything geared toward a 30 degree measurement – two 15 degree sides – to ensure everything came out well. After the initial grind on the rough setup, I used the grading stone to make the wheel smooth and proceed to the honing. After that, a quick spin on the leather stropping wheel, and this baby was ready to cut.

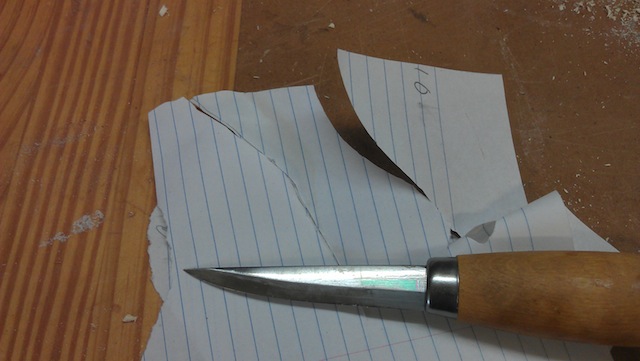

Yeah, a clean slice through a piece of paper is a very good indication that I nailed it. With my new sharp knife, I’m looking forward to trying my hand at carving – or fending off other ravenous picnic goers who get too close to my fried chicken!